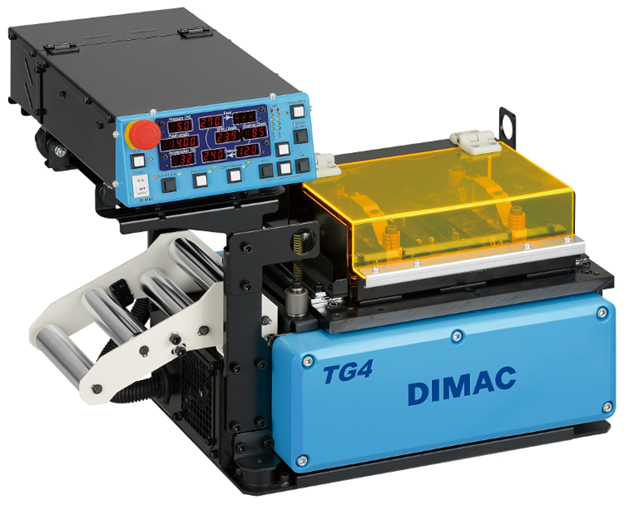

The slowest R and J series, up to 300 strokes/min, make it possible to feed larger strip sizes, have a pneumatic roller opening, and can be connected to the press with mechanical or electronic cam systems.

The setting only requires pitch length, feed angle, and reference speed of the press.

FEATURES

- Maximum reliability and precision

- Easy programming with data visualisation

- Quick selection of feed pitch, working angle and speed

- Quick replacement of control unit by connectors

- Easy installation without the need for specialised personnel